QUALITY CONTROL

|

QUALITY CONTROL

We are strongly committed to quality and quality control systems are accredited to ISO: 9001/TS 16949. The document control system goes through all the production & quality control inspection processes. We have independent quality control department who controls every plastic mold and plastic molding parts quality inspection step from incoming material, production process of mold making and plastic molding, assembly, packing, as well as cargo shipment.

We have established quality evaluation program for each process to assure our customer the best quality products and most professional service. We own a full set of advanced measuring and testing equipment, our can provide a series of testing reports upon customer’s request at any time such as CPK, FAI, PPAP, PFMEA and so on.

|

|

|

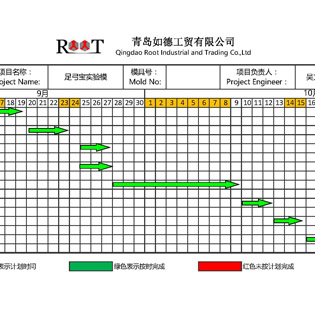

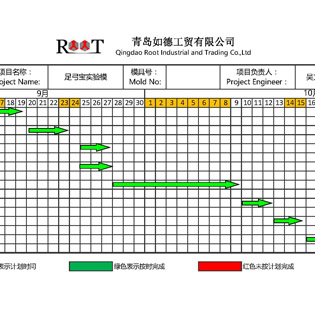

DELIVERY TIME

[design management] using parallel and standardized design, the use of diversified design software and fast communication tools, effectively shorten the design cycle 1/2, save the cycle at least 3-5 days;

[logistics and transportation] scientific U type logistics plant design, rhythm of the main material pulling management, systematic production materials zoning, classification, positioning management, effectively improve the efficiency of mold production;

[plan management] the application of advanced APS scheduling system and ERP system, reasonable allocation of people, objects and machines, real-time monitoring of production schedule and resource load, to achieve 0 delays in mold production;

[manufacturing] through processing optimization and automation programming popularity, effectively improve processing efficiency, shorten the processing cycle of parts.

|

|

|

Ingenuity

"Where I post is the most extraordinary company positions, my hands are the most precious family" weapons ", I want to send out the workpiece from my hand, every one of them is the perfect work of art."45 degrees sandpaper grinding angle, pure hand polishing process, pay attention to the subtle skills; 25%, two grinding time, it is related to the surface of the mold to eliminate the extent of sand.The surface roughness reaches m, which looks like a mirror.

|

|

EXQUISITE STRATEGY

[precision capability] High precision precision parts processing progress to + 0.001MM, injection molding / stamping die accuracy of + 0.01MM, precision stamping die accuracy of + 0.002MM.

[ability] Has equipment of precision machining equipment, all imported from Japan, Makino, Toshiba, MITSUBISHI top equipment, standardized equipment management is realized through the similar brand and type selection of equipment, Makino CNC, EDM equipment processing precision may reach 0.01mm; 26 MITSUBISHI WEDM equipment for processing accuracy of 0.003mm.

|

|