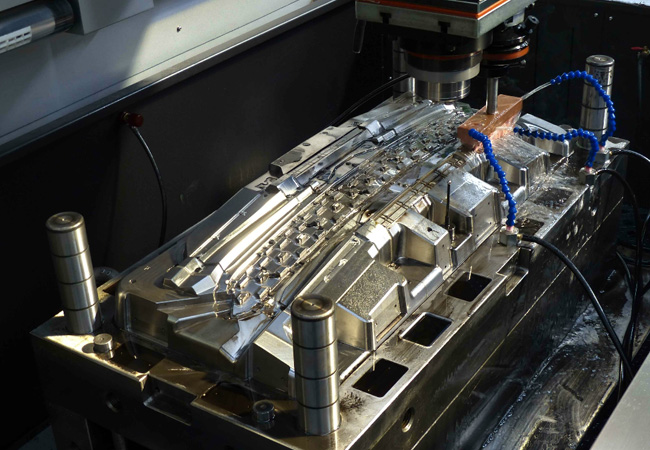

In order to determine the damage status of the mold and maintenance measures. Processing enterprises should be in the injection molding machine, the normal operation of the mold, the test mold a variety of performance, and the final shape of the plastic parts measured by this information can determine the existing state of the mold, find the cavity, core, cooling System and sub-surface damage.

At the same time to focus on several important parts of the mold to track the detection: the role of the top, guide parts to ensure that the mold opening and closing movement and plastic parts of the top, if any part of the damage due to injury and stuck, will lead to shutdown, To maintain the mold thimble, guide column lubrication (to choose the most suitable lubricant), and regularly check the thimble, guide column, etc. whether the deformation and surface damage, once discovered, to be replaced;

After the completion of a production cycle, the mold working surface, sports, guide parts coated with professional anti-rust oil, in particular, should pay attention to with gears, rack mold bearing parts and spring mold elastic strength protection to ensure that its always In the best working condition;

With the production time is continuous, the cooling channel is easy to deposit scale, rust, sludge and algae, so that the cooling channel cross section becomes smaller, cooling channel narrowing, greatly reducing the coolant and mold heat exchange rate between the increase in production costs, So the clean-up of the flow channel should pay attention;

For the hot runner mold, heating and control system maintenance is conducive to prevent the occurrence of production failures, it is particularly important. Therefore, after the end of each production cycle should be on the mold belt heater, bar heater, heating probe and thermocouple with ohm meter to measure, if damaged, to be replaced, and with the mold resume Compare, make a record, in order to find the problem timely, to take countermeasures.

Mold surface maintenance can not be ignored, it directly affects the surface quality of the product, the focus is to prevent corrosion, therefore, choose a suitable, high quality, professional anti-rust oil is particularly important. When the mold to complete the production tasks, should be based on different injection to take a different method to carefully remove the residual injection, copper rods, copper wire and professional mold cleaning agent to remove residual mold injection and other sediment, and then air-dried.

Disable wire, steel and other hard objects to clean up, so as not to scratch the surface. If there is corrosive injection caused by the rust point, to use grinding grinder grinding, and sprayed with professional anti-rust oil, and then placed in a dry mold, cool, no dust at the storage.

-

About us

-

Products

Plastic Mould

Injection Molding

Casting Mould

Stamping Mold

CNC Machining

Others

-

News

-

Quality Control

-

Contact us

Cell: +8618766209935

Tel: +86-532-68988895

Fax: +86-532-68988895

E-mail: sales@rootsino.com sales@rootchina.cn

Address:No.23,Tian Shan 3 Road,Jimo,Qingdao,China